Modern systems and technologies

BUILDING CONSTRUCTION

Construction of quality structures according to approved drawings is one of today’s concerns in the field of construction of the country. In this regard, this engineering group, having obtained a license from a Ministry of Housing and Urban Planning, has a well-trained and trained staff ready to implement construction projects and projects as contract management, and so far has implemented projects in the city of Tehran. .

Execution of concrete and steel buildings

Execution of the ancient building of the bridge

SEISMIC OPTIMIZATION AND RETROFITTING

Seismic optimization means improving the seismic condition of existing structures.

In order to improve the seismicity of the target structure, it is equal to building the seismic capacity of the structure that can be achieved by increasing the structural capacity or by reducing the need for seismicity.

Increasing the structural capacity is possible with increasing hardness and resistance, which is called refinement. Building retrofitting can be done using modern building materials and products such as FRP.

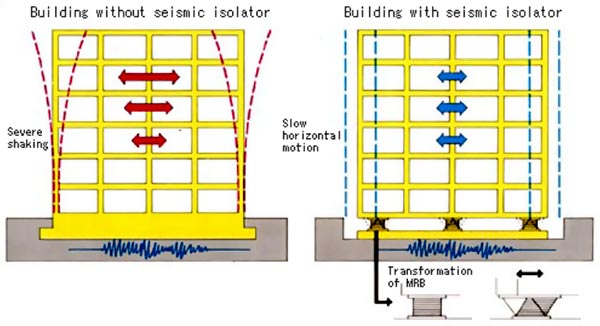

The reduction of the structural seismic requirement can also be accomplished through various measures such as: increased formability, reduced mass, reduced irregularities, and the use of modern seismic designed technologies, such as the use of seismic separators, dampers, etc.

In presenting the improvement plan, it is necessary to pay attention to the two categories of execution and economic efficiency of the plan, as the improvement of the shivering motion is on the edge of the razor.

If the designer, in his/her plan, did not use the full capacity of the structure, he/she would lose his/her economic justification and the modernization will be improved upon.

It should be noted that using nonlinear analyzes can be used to fully utilize the structural capacity.

One of the basic activities of the construction group is designing and implementing retrofitting and improving the seismicity of the buildings under construction. In this regard, several projects have been designed and implemented in the country.

MODERN SYSTEMS AND TECHNOLOGIES

Wallcrete Panel Super-Concrete Walls

WALLCRETE Wallcover Wall is actually a panel of lightweight reinforced concrete with polymeric and mineral fibers using nano fillers and in much larger pieces than conventional blocks. This product meets the needs of industrialization and features such as sound insulation, heat insulation and cooling, ultra-lightweight, reducing structures and foundations weight, suitable for high-tension, high speed execution, and optimization of the interior.

WALLCRETE Wallcover Wall is actually a panel of lightweight reinforced concrete with polymeric and mineral fibers using nano fillers and in much larger pieces than conventional blocks. This product meets the needs of industrialization and features such as sound insulation, heat insulation and cooling, ultra-lightweight, reducing structures and foundations weight, suitable for high-tension, high speed execution, and optimization of the interior.

In order to upgrade the knowledge and services of engineering and application of new systems, BastanPol Imen has acquired Robinson’s products sales in the provinces of Khorasan and Guilan.

In general, energy absorbers and separators are used to reduce the dynamic response of the structure to wind and earthquake pressure . The functional mechanism of these devices is performing special deformations and special mechanical actions. Through these actions they absorb a large amount of energy input to the structure due to dynamic pressure . The function of these dampers reduces the energy received by other structural members and, as a result, does not cause much deformation. Energy dissipation in these dampers occurs as the conversion of kinetic energy into heat by friction, movement in slurry, metal surrender, and so on.

The advantages of using separators and dampers can cause a significant increase in the level of structural performance, reducing the structure of the seismic response up to 20%, a significant reduction in non-structural damage, reducing the volume of materials needed for construction, the usability to improve existing structures, And in some cases the recovery of the initial shape and zero need for replacement after the earthquake

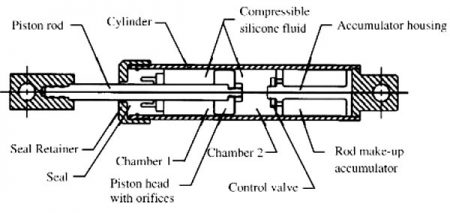

The structure of a slurry liquid dampers generally consists of a piston and a cylinder. Slippery fluid inside the cylinder is compressed by the piston, inside the piston. there is another cylinder that can be introduced through the liquid perforations. By applying the pressure to the fluid system, the fluid exchanged between the two cylinders loses a lot of energy.

This type of damper acts on the basis of the friction mechanism between rigid bodies relative to each other. In fact, friction is a great energy dissipation mechanism. The function of all friction dampers is that one part is fixed and the other part slides down dynamically. The slip occurs at a certain level of force, so that no movement happens up to a certain level of force, but after this level, slip and motion begins. The composition and positioning of these slip surfaces creates different friction dampers.

3. YIELDING DAMPER

The function of these dampers is based on the surrender of the metal and thereby increase the energy dissipation capacity. In fact, these dampers are flooded during pressure and, as a result, deplete a large amount of input energy into the structure. In this way, no further degradation occurs on the structure of the building, but on a predetermined piece which, after pressure, is also interchangeable. The disadvantages of this method can be the permanent deformation after the earthquake.

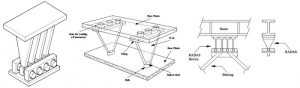

Seismic separation is the separation of the whole or part of the structure from the ground in order to reduce the seismic response of that part at the time of the earthquake event. Seismic separation systems have been accepted as one of the most effective ways of protecting structures against seismic stimulation. These systems reduce the response of the axes, in particular the relative displacement of the classes and the acceleration of the classes. However, the base displacement of these systems in the near-field earthquakes can be increased, which should be provided by creating space around the building.

Since 2012, the designer BastanPol Co. has taken steps to implement one of the structural properties of the steel sheared walls, which in recent years has been a particular interest to engineers internationally. The company’s know-how and technical capabilities, together with a collaborative academic effort with Amir Kabir University of Technology, have led to the publication of credible scientific articles at international conferences and journals.

1- Benefits of steel shear walls system

1-1- General benefits– Weight loss of steel consumption

The low weight of the steel plate, the simplification of design requirements due to the proper behavior of the system (and having a high operating coefficient), along with the effective performance of controlling structural deformations due to the high degree of hardness, can lead to a reduction in the weight of the designed skeleton

– Safety and high seismic resistance due to the continuity, ductility and strength of steel plate and joints.

– Easy implementation due to:

– Use of joined joints with corner weld on all frame joints, except for connecting parts of the steel plate

– Easy to carry and easy installation of steel plate due to low weight, high flexibility and cutting and preparation at factory site.

– The small size of the welding part of the steel plate connection and its implementation is only one pass (welding). It is also possible to remove the weld and implement the connection with the help of bolts and nuts.

– Less occupation of architectural space than other lateral load systems

– Possibility of opening the door (door or window): In steel sheared walls, regarding to the necessary hardening, there is the possibility of opening a gap in any place, while this possibility is limited in the V-bracing system and does not exist in the X curtain and in Concrete sheared walls with limited size and difficult execution details are encountered.

1-3- Behavioral Benefits– Density and higher energy absorption than reinforcing concrete sheared reinforcement systems.

– The lack of specific sensitivity to the implementation of fusion joints, in contrast to the framing pane, in which, in the event of failure of the connection weld under the lateral pressure, floor decay and progressive deterioration occurs,

– The safety provided by the steel sheared wall is comparable to the unconstrained steel grade and the weld joints used in connecting it to the bracing system and the framing pane and with the reinforced concrete sheared wall system.

– In the system of steel sheared walls in the event of an earthquake, the submission and failure in the steel sheet is interchangeable and to a lesser extent in the ends of the upper and lower beams, and the other beams and structural columns will remain safe from the occurrence of surrender, thus the cost of reconstruction Building after earthquake is minimized.

– Up to 50% less skeletal structure. The more advanced sidewall stiffness of the steel sheared wall compared to the framing panes allows more effective control of structural deformation. This factor, coupled with the higher-performance behavior of the system (up to 2.5 times), which reduces its seismic pressures, dramatically reduces the weight of the skeleton.

– Faster and quicker implementation: Full penetration of flexural fusion joints leads to difficulty and slowness, while in the steel sheared wall system, other than joints in the wall openings the rest of the connections are joint like.

– Weight loss. Consumed steel: In the event of the use of a dual system due to the weakness of the bracing system in controlling deformations, the use of a steel sheared wall system will only be sufficient due to the higher hardness. Having a higher behavioral factor (up to 1.7 times) will also help reduce skeletal weight.

Better Seismic Behavior: In seismic bracing systems, the focus is on the joints, while in the steel sheared wall system, these forces are distributed by the wall plate at all points of the beam and the surrounding columns.

– Lower weight: Significant weight of the concrete wall, in addition to overlaying the lower beams, results in a significant increase in the weight of the structure and seismic forces absorbed.

– Higher treatment coefficient: Regardless of the dual system “Special Fender Frame + Reinforced Concrete Reinforced Concrete Wall” which is considered less due to the specific problems of the operation, the system behavior of the steel sheared wall system is 1 to 25 times the concrete equivalent. It is furthermore that, in proportion to this increase in seismic pressure, also decrease.

– The implementation process is much simpler: Due to the steps of armature, molding, concrete fastening and molding in the process of implementing a concrete sheared wall, the implementation of the steel sheared wall system is far faster and easier.

| Compare the parameter | Structural system | |||

|---|---|---|---|---|

| Steel shear wall | Medium Framing Frame (Special) | Braided braided frame (outboard) | Concrete Shear Intermediate Wall (Special) | |

| Behavior factor | ۱۰ | ۷ (۱۰) | ۶ (۷) | ۷ (۸) |

| Side difficulty | High | Low | medium | too High |

| The dead load is due to the weight of parts other than the beam and the column | very low | —— | medium | High |

| Speed and ease of implementation | آسان | medium | medium | دشوار |

| The amount of occupancy of architectural space by structural skeleton | very low | High | High | very High |

| Possibility to expand | مقدور | بدون مشکل | غیر ممکن (محدود) | پرهزینه و خیلی دشوار |

| Structural safety | خیلی زیاد | medium(زیاد) | کم (medium) | High |

| The cost of rebuilding and re-utilization after an earthquake | very low | very High | High(very High) | very High |

| The need for a specialist force to build | no | yes | no | yes |

2- History of the steel shear wall

Several cases of use of the system in the 1970s can be reported in countries such as Japan and the United States, but by presenting the rules for the design of steel sheared walls by the US Steel Structures Seismic Design Regulation (AISC 341) in 2005, the development of a significant speeding system is found and Several recent uses of this system can be cited, some of which are referred below.

– – A 30 storey hotel in Las Vegas (pictured p. 23)

– Silomar 6 storey Hospital in Los Angeles (1980) (p. 3)

– Structural system: In the first two floors, a steel frame with a concrete slab and a four-storey steel sheared wall.

– The reason for the use of steel sheared walls is based on the report: the weight of steel consumed by up to 50% compared to the steel framing pane, the weight reduction of the structure by removing the reinforced concrete sheared walls, the optimal use of the useful space of the architecture, increased run speed, the possibility of embedding Pop-up (door and window) desired.

– The Silomar Hospital had only minor damages in the Whittier and Northeastern earthquakes (1987 and 1994).

– Building the 22nd Justice Department in Seattle, Washington (p. 23).

– A 52-storey building in San Francisco, CA (p. 23)

– ۵۲storey office building in Tokyo (1975) (p. 22)

– ۲۰ floors office building in Tokyo (1970) (p. 22)

– ۳۵floors Japan Coupe Tower (p. 19)

– The structural system of this building is a dual framing system with a steel sheared wall. It was constructed in 1988 and exposed to the Kobe earthquake in 1995. Post-earthquake studies on this structure showed that no general damage was reported and all damage was minor.

– ۷۵storey building in Tianjin, China (p. 23)

3- Design guidelines

The activities of the ancient engineering group in the field of domestication and implementation of steel sheared walls system in Iran

Due to the complicated and time-consuming design of the steel sheared walls (referred to in Section 1-4), one of the major obstacles to extending the use of this system is the current structure design software, lacks the ability to design the system. To solve this problem, the experts of BastanPol, in cooperation with Amir Kabir University of Technology, have developed a software for the design of steel sheared walls. Using this software, the company can test the various options and help to achieve the best design. In addition, with this software, it is possible to provide a design calculator so that the accuracy of the performed calculations can easily be achieved for audiences with technical knowledge and legal references.

– Design of a steel sheared wall system based on the US Steel Structural and Steel Structures (AISC-341) and its Interpretation

– Reduce the time of repetitive process and time on the design of sheared steel manually with a much faster software product.

– Reducing errors caused by human factors and eliminating the inevitable approximations of the manual method

– Ability to map executive details automatically

– Possibility of using columns of concrete canisters filled with concrete to reduce the sizes of the columns and the weight of steel used and …

– A project of 10 residential floors with an area of 770 square meters per floor and a total area of 7700 square meters

– Project location: Frontier zone in Tehran

– Structural Ceiling System: Conventional Composite

Design of the structure with three options: “Special steel folding frame”, “Flexible framing pane + Modular sheared wall” and “Fully sheared wall system”

The steel used in the two systems “Special steel frames” and “Framing pane + Reinforced concrete sheared walls” is intended for use with the St37 type and used in the construction of the columns of the two systems from the sections of the can.

In the steel sheared wall system, the columns are selected from sections of concrete filled cups (CFT). ST52 is used to build columns and beams around the walls. The connection of the beams to the columns is considered to be of the branch type of RBS. The used steel sheets have a minimum thickness of 3 mm and are of ST37 steel type.

The steel weight used per square meter of infrastructure is compared in the following table for different options:

| بخش سازه ای | سیستم سازه ای | ||

|---|---|---|---|

| دیوار برشی فولادی | قاب خمشی فولادی ویژه | قاب خمشی فولادی + دیوار برشی بتنی متوسط | |

| تیر و ستون های اسکلت | ۵۵ | ۸۰ | ۶۰ |

| اجزای اتصال تیر و ستون های اسکلت | ۵ | ۱۶ | ۱۲ |

| سقف سازه ای | ۱۵ | ۱۵ | ۱۵ |

| مجموع | ۷۵ | ۱۱۱ | ۸۷ |

DESIGN AND CONTROL OF THE STRUCTURE

The structural design and control department of this engineering group has started its work in 1997 and has been able to design and perform structural calculations for more than one year with the experience of various projects with different uses and specifications, in cooperation with the forces and experts who have specialized in the field of structures. Out of 1,200 small and large projects with different instrumentation systems.

With the backing of 18 years of experience and knowledge, we are able to design specific structures and claim the design of complex and unusual architectural designs according to the rules of the day in Iran and the world. Meanwhile, the group is ready to control the calculations and to report any points or probabilities.

Regulations used:

Software used:

- ETABS ver: 9.7.4&2015

- SAP ver: 14

- SAFE ver: 8&14

- AUTOCAD ver: 2015

- SAZE90

- SAZENEGAR

- TEKLA ver:19

- REVIT ver: 2016

- ADVANCE STEEL ver: 2016

Description of the services of the structural design department:

- Choosing the system for proper gravity pressure

- Selection of a suitable instrument for the lateral pressure at height

- Choosing the right roof system for gravity and seismicity

- Complete design of the base system

- Design of supporting elements (braces, sheared walls, bending frames)

- Full design of fittings and patches

- Design and presentation of connecting elements of non-structural elements, expansion joints and separator walls

- Adaptation of detailed maps of the implementation of the Foundation with design

- Concrete building (if selected):

- Planning instructions, sheared wall and beam shapes

- Edge map of column, beam, sections and connecting level

- Ceiling grid and sections

- Positioning and displaying details of grinding at the beginning of openings and holes (installations, etc.) in covering the ceiling of the floors and their depth and their size in the walls and showing the details of the grinding in the place of dense nodes

- Determine the type of patch, range, position and density of the bars in the beams, pillars and slab

- Steel building (if selected):

- The essential details of the flexural and composite space frame

- Details of the footprints of the columns and how they connect to the foundation and the details of the stepping sword

- Plank Types of columns, pistons, beams, and braces or sheared walls with full details.

- The type of electrode, the length and size of welding, and the location of its execution

- The location and size of the installation duct and the drawing of details around the perforations

- Details of the connection of concrete beams or concrete slabs or other parts to the steel beams and edge beam

- Execution details of the edge console in terms of how to connect to the skeleton

WHAT IS VALUE ENGINEERING?

Value engineering is a systematic, creativity-based, and task-oriented team to solve the problem, reduce costs and improve the performance and quality of projects, products, and processes. Value engineering, with the help of a wide range of expert’s knowledge and experiences, focuses on the functions of the project, the product, or the process of delivering results that can be improved.

According to the definition of the International Institute for Project Management, Creative Value Atomic Engineering is designed to optimize lifecycle costs, save time, increase profits, improve quality, increase market share, solve problems and make optimal use of resources.

According to the Definition of the Strategic Planning and Control Office of the President, the value engineering is the well-known use of techniques used to examine the performance of a product or service, and using creative thinking to provide the function needed to achieve the objectives of the plan. Sure and with the least cost of life and maintaining or enhancing the quality and maintaining the safety and environmental characteristics.

Bastanpol Engineering Group is proud to take steps to optimize structures and reduce administrative costs, to carry out the engineering process of value in buildings, and to acquire value added for respectable employers, and has several completed projects.

STRUCTURAL SUPERVISION:

The construction supervisory team of the BastanPol Engineering Group consists of experienced engineers in this field who during the structure’s execution from the beginning of the excavation to the end of the structure, are present at the workshop and factory site and the supervision of the proper implementation of the structure is executed in two types of superficial supervision and workshop supervision based on the description.

The following services are provided.

Description of Structural Supervision and Workshop Supervision:

A: ngineering Services:

- Review the design of the structure if necessary, and propose changes.

- Reviewing the report of geotechnical tests and proposing the optimal guard system for guarding the structure if needed, and announcing it to the employer.

- Determine the method of monitoring the structure and determine the stages of the visit due to the difficulty of work.

- Preparing forms and agenda forms and periodic reports

- Provide a list of test labs.

- Preparation of instructions for storing materials and equipment in the workshop’s warehouse

- Possible revisions in maps and technical specifications according to requirements of the executive, the preparation of maps and corrective documents in order to adapt to the findings and new conditions.

- Compilation of detailed maps and executive detailed map to complete the work in such a way that there is no bottleneck or problem caused by a map or agenda defect.

- Preparation of checklists related to the implementation of structures at different stages of the work to control the quality of implementation

B. Referral Services:

- Referral of the required services required during the construction period, such as mapping, geology, geotechnics , geophysics and guard structures, resistance of materials and welding tests, etc., including the determination of the process of selecting a consulting unit A, obtaining the approval of the employer regarding the proposed method and performing referral work which Employer’s request if needed.

- Selection of the most suitable unit for the performance of any of the related services and the offer of the selected company to the employer.

C. Coordination, executive, temporary delivery

- Investigation and approval of proposed methods of contractors.

- Participation in coordination workshop meetings with the presence of supervisory machinery, employer and contractors and other agents engaged in scheduling meetings, handling issues and barriers in implementation of work, registration and decision minutes.

- Checking the skill and technical skills of those involved in sensitive work, such as welding and concrete

- Checking and confirming the contractor’s request regarding the availability of work for temporary delivery, inspection and control of performed work, confirmation of the availability of work for temporary delivery and operation or declaration of non-preparation for exploitation, with a list of deficiencies that prevent the exploitation and its announcement to the employer,and supervision over defective operations.

D. Quality control services

The services of this part include controlling the quality of materials, equipment, and work performance:

- Carrying out periodic inspection and controlling the operation of the workshop and the factory for the implementation of construction operations with maps and technical specifications, standards and orders, and the order of testing, and verification of tests performed such as welding tests, etc., and confirmation or non-approval of the product Produced and provide a list of defects in the event of non-approval and follow-up of product defects until final approval.

- Measuring deformations, displacements and controlling permissible tolerances.

- Preparation of the plan and order for testing and control and verification of the diversity of material tests such as concrete, reinforcement, welding test, etc., and monitoring the sampling.

- Controlling and verifying the results of tests, communicating an order to the contractor for the repair of materials, equipment or defective works.

- Instructions for correcting defective tasks and tracking and fixing them.

- Approval of specification of materials and equipment to be used in work in terms of compliance with technical specifications and executive plans.

- Handling and commenting on workshops and Shop Drawing provided by contractors.